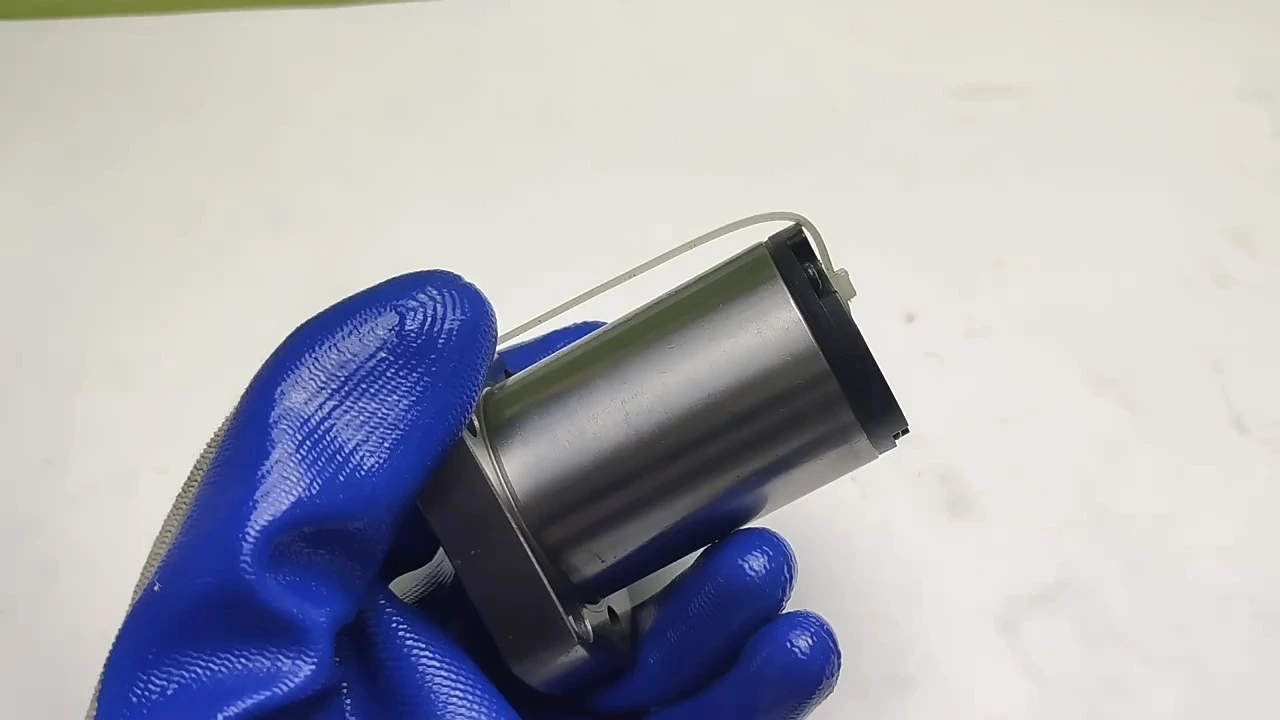

SFS2525 Ball Screw 25mm Diameter Precision Ground Ball Screw for CNC & Automation

| Model | SFS2525 |

| Shaft Diameter | 25 mm |

| Lead (Pitch) | 25 mm |

| Accuracy Grade | C5 / C7 (optional C3) |

| Nut Type | Flange / Cylindrical |

| Recirculation Type | Internal or End-cap return |

| Material | GCr15 / SUJ2 bearing steel |

| Hardness | HRC 58–62 |

| Efficiency | ≥ 90% |

| Preload | Optional (light / medium / zero-backlash) |

| Dynamic Load Rating | Based on nut size and preload |

| Operating Temperature | –20 °C ~ +80 °C |

| Lubrication | Grease or oil ports available |

| Length | Customizable (per order) |

Product detail

The SFS2525 Ball Screw is a precision ground linear motion component engineered for demanding automation and CNC applications.

It features a 25 mm screw shaft and 25 mm lead, ideal for systems requiring high-speed, long-stroke, and stable linear transmission.

With its recirculating steel ball design, the SFS2525 achieves over 90% transmission efficiency, reducing friction and ensuring smooth, accurate positioning.

Manufactured from high-grade bearing steel (GCr15 / SUJ2) and treated through heat-hardening and precision grinding, it delivers outstanding rigidity, durability, and long service life — even under continuous heavy-load operation.

Key Features

25mm Shaft Diameter / 25mm Lead: High-speed transmission with fast linear displacement per rotation.

High Efficiency & Low Friction: Smooth recirculating motion achieves up to 90–95% efficiency.

Precision Ground Threads: Ensures consistent lead accuracy and low vibration.

Zero Backlash (Preload Optional): Tight preload options maintain accuracy under heavy loads.

Heavy Load Capability: Large ball contact area increases load rating and stiffness.

High Rigidity & Stability: Designed for precision motion with minimal deflection.

Durable Construction: Made from hardened bearing steel for extended lifetime.

Interchangeable Design: Compatible with standard SFS nuts and flanges.

Product parameters

Applications

The SFS2525 series is widely used in CNC machines, automation equipment, robotics, and precision linear modules that demand consistent, low-backlash motion.

CNC milling machines and routers

Automation and robotics systems

Linear motion modules and actuators

Precision positioning stages

Laser cutting / engraving machines

Semiconductor and optical equipment

Packaging and pick-and-place machines